Zero Liquid Discharge (ZLD): A Comprehensive Overview for WasteWater Discharge

Contents

Introduction:

Zero Liquid Discharge (ZLD) is a cutting-edge water treatment processdesigned to eliminate wastewater discharge, transforming it into reusable water and solid waste. This technology tackles environmental concerns like water scarcity and pollution while offering economic benefits by reducing water acquisition and waste disposal costs.

Principles and Benefits:

ZLD aims to recover all usable water from wastewater, leaving behind only solid waste. This approach offers several advantages:

- Reduced Waste Management Costs: The foundation of ZLD systems is to minimize liquid waste through water recovery and transformation of contaminants into solid form. This significant reduction in liquid waste volume directly translates to lower disposal expenses for industries. Traditional waste management often involves costly treatments, transportation, and disposal fees for liquid wastes. By minimizing the volume of liquid waste, ZLD systems help industries reduce these operational costs significantly. This cost efficiency becomes especially valuable in sectors where waste disposal expenses constitute a considerable portion of operational budgets.

- Lower Water Acquisition Costs: ZLD systems recycle and purify wastewater on-site, turning what would be waste into a valuable resource. This on-site recycling capability diminishes the need for external water procurement, thereby reducing both the costs and risks associated with water sourcing. In regions facing water scarcity, the cost of water acquisition can be high, both financially and in terms of sustainability. By utilizing ZLD, industries can become more self-sufficient, lessening their dependence on municipal water supplies or other external sources, which may be costly or subject to restrictions during drought conditions.

- Environmental and Social Benefits: By reducing greenhouse gas emissions related to the transportation of wastewater for off-site treatment or disposal, the installation of ZLD systems directly benefits the environment. Reducing the need for transportation results in a lower carbon footprint and fuel consumption, which supports larger initiatives to fight climate change. Furthermore, ZLD lowers the possibility of mishaps and spills that can endanger nearby communities and ecosystems by reducing the amount of waste transported. This feature helps the environment and raises the bar for businesses' social responsibility.

- Enhanced Regulatory Compliance: ZLD enhances an organization’s ability to comply with environmental regulations. Many regions around the world are tightening regulations on industrial wastewater discharge, imposing stringent limits on pollutants and mandating higher levels of water reuse. By adopting ZLD, industries can meet or exceed these regulatory requirements, avoiding potential fines and sanctions. Moreover, ZLD can improve a company’s environmental performance, making it a more attractive partner or supplier to environmentally conscious businesses and consumers, and potentially easing the process of obtaining permits for expansion or new projects.

- Resource Recovery: ZLD's capacity to extract priceless resources from wastewater streams is among its most alluring features. Commercially valuable minerals and salts can be extracted by ZLD systems using processes like evaporation and crystallization. Examples of salts that industries can recover include potassium sulfate, which is used as a component of fertilizer, and sodium chloride, which is used to de-ice roads. These salts can also be sold. By converting waste into resources, this not only adds another source of income but also lessens the environmental effect of industrial operations by promoting the circular economy.

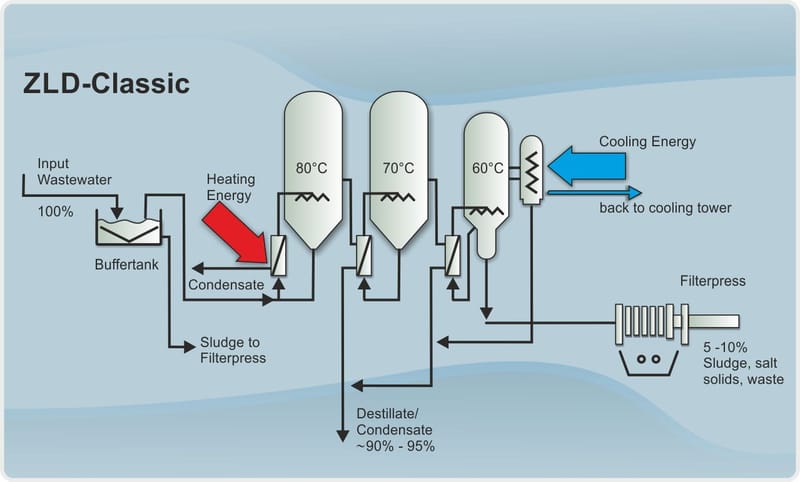

A typical ZLD system comprises several key components:

- Pretreatment: This stage involves the initial removal of contaminants from the wastewater, preparing it for further purification steps by filtering out solids and certain dissolved substances.

- Evaporation/Crystallization: At this phase, water is evaporated, leaving behind concentrated salts and solids. The crystallization process then solidifies these residues, separating them from the purified water.

- Membrane Processes: These technologies, such as reverse osmosis, are employed to concentrate the brine further before it undergoes evaporation. This step is crucial for reducing energy consumption in later stages.

- Solid Waste Treatment: The final step involves the management and disposal of the solid residues generated during evaporation and crystallization. This includes safe handling, transport, and disposal or recovery of materials if applicable.

These systems find applications across various sectors, especially in water-scarce regions or industries handling hazardous materials, including power generation, chemical manufacturing, pharmaceuticals, textiles, and mining.

Obstacles and Prospects for the Future: Difficulties in Applying ZLD

- High Capital and Operational Costs: ZLD systems come with a hefty initial investment and continuous operating costs because they require advanced technology and equipment. Energy-intensive procedures such as crystallization and evaporation add to high operating costs, requiring a significant financial outlay from businesses.

- Difficulty of Integrating Various Treatment Technologies: ZLD requires a number of treatment phases, such as membrane processes, evaporation, crystallization, and pretreatment. To ensure efficiency and effectiveness, each step needs to be carefully integrated, which calls for specific knowledge and experience. This intricacy can make it difficult to efficiently design and run ZLD systems.

- Maintenance Problems: Scaling and equipment fouling can result from the high concentration of contaminants in the wastewater treated by ZLD systems. The operational challenges are increased by the need for routine maintenance and cleaning to ensure optimal system performance and prevent downtime.

- Solid Waste Disposal Requirements: ZLD systems greatly minimize liquid waste, but they also raise the quantity of solid waste that requires management. More preparation and funding are needed to dispose of this solid waste in an economical and environmentally responsible manner.

Future Advancements in ZLD

The future of ZLD technology is focused on addressing these challenges through innovation and improvements in several key areas:

- Reduction of Energy Consumption with Energy Recovery Systems: By repurposing and capturing heat from the ZLD process, energy recovery technologies seek to drastically lower the energy needed for evaporation and crystallization. This can increase ZLD systems' overall sustainability and reduce operating costs.

- Creation of More Efficient Membrane Technologies: Reducing the energy usage of ZLD systems requires significant advancements in membrane technology. Reverse osmosis is one of the new materials and designs being developed to improve the efficiency of membrane processes, lowering energy requirements and reducing scaling and fouling problems.

- Use of Renewable Energy: By compensating a portion of the energy demands, ZLD platforms that incorporate renewable energy sources, especially solar or wind power, may reduce the cost of operation and reduce the environmental impact of the wastewater treatment procedures.

- Enhancing the Efficiency of Resource Recovery Techniques: Subsequent research will also focus on refining the method of obtaining valuable substances from wastewater. ZLD systems may enhance the processes used to extract nutrients and other valuable materials, reducing waste and opening up fresh revenue streams for organizations.

Environmental and Regulatory Drivers:

ZLD adoption is driven by:

- Stringent environmental regulations

- Corporate sustainability goals

- Recognition of water as a finite resource

Countries facing water scarcity and pollution have implemented ZLD regulations, making it crucial for industrial water management strategies.

Advanced Technologies and Practices:

Beyond the foundational knowledge, let's explore advancements in ZLD:

- Advanced Oxidation Processes (AOPs): Degrade resistant organic pollutants using highly reactive species.

- Electrocoagulation and Electrodialysis: Remove impurities using efficient electrochemical methods.

- Zero Liquid Discharge in Desalination: Maximizes water recovery and minimizes brine discharge impact.

- Hybrid Systems: Combine thermal and membrane processes for optimal efficiency and reduced costs.

- Artificial Intelligence (AI) and Machine Learning (ML): Optimize operations, predict maintenance needs, and reduce energy consumption through data analysis.

Sustainability and Global Adoption:

- ZLD contributes to the circular economy by recovering resources and reducing waste.

- Advancements focus on reducing energy consumption and emissions, aligning with sustainability goals.

- Global adoption varies, influenced by regulations, water scarcity, and industry needs.

- Stringent regulations and water scarcity drive ZLD adoption, with government incentives or mandates in some cases.

- The evolving regulatory landscape is expected to continue driving global ZLD adoption.

Final Thoughts and Inference:

ZLD is at the forefront of addressing water scarcity and pollution challenges. Continuous innovation makes ZLD systems more efficient, sustainable, and economically viable. As we strive towards sustainable water management, ZLD stands out as a key technology for future advancements in water treatment and conservation.