Introducing the MBBR Bioreactor A Revolutionary Solution for Wastewater Management

Contents

- A Step Forward in Sustainable Treatment of Wastewater

- Understanding the Mechanics of MBBR Technology

- The Internal Workings of an MBBR System

- Superiority Over Traditional Treatment Approaches

- Broad-Spectrum Applications: From Industry to Municipality

- Benefits of MBBR over Traditional Processes:

- Envisioning the Future of Wastewater Treatment

- Conclusion: MBBR as a Beacon of Innovation in Wastewater Management

A Step Forward in Sustainable Treatment of Wastewater

In the constantly evolving environment of environmental conservation and water management, the Moving Bed Biofilm Reactor (MBBR) technology symbolizes a significant milestone. The aforementioned complicated biological treatment approach outperforms standard systems by combining the benefits of biofilm and activated sludge processes. As worldwide environmental constraints tighten and the demand for water reuse grows, MBBR emerges as a versatile and effective response to modern wastewater treatment issues.

Understanding the Mechanics of MBBR Technology

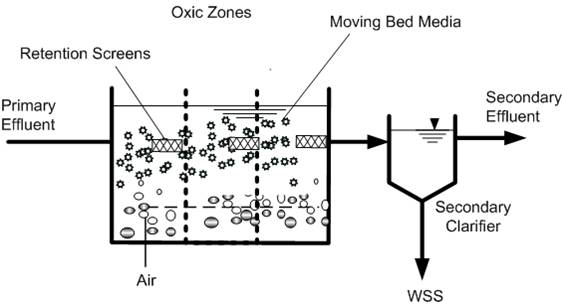

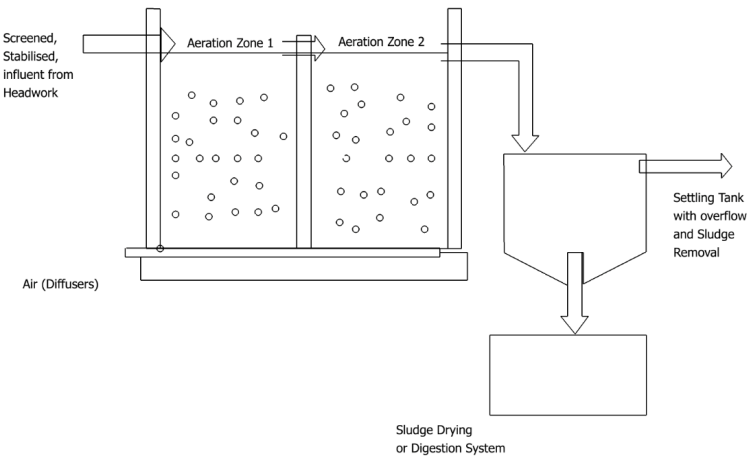

Moving Bed Biofilm Reactor (MBBR) technology was developed in the late 1980s by a dedicated group of Norwegian researchers in response to the limitations and challenges that traditional wastewater treatment systems came across. The innovative use of polyethylene carriers, precisely designed to foster and nourish the development of biofilm, is vital to MBBR technology's invention. When these carriers are put into an aerated tank, they transform the space into a vibrant ecosystem filled with microbial life dedicated to the cleaning and breakdown of incoming wastewater. This microcosm, like a bustling metropolis center, consists of many microorganisms working tirelessly in conjunction. Their combined action is geared towards the efficient and effective elimination of these contaminants, with each microbe playing an important role in the overall process of wastewater treatment.

The aeration grid, cleverly placed at the bottom of the tank, is a critical component that ensures the MBBR system runs smoothly. This characteristic not only allows for the crucial entrance of oxygen by replicating the system's lungs, but it also generates a dynamic environment in which biofilm carriers are constantly in motion. This mobility is critical for minimizing stagnation, guaranteeing a uniform distribution of carriers throughout the tank, and so improving the interaction between wastewater and biofilm. The aeration grid's twin role of supplying oxygen to the water as well as maintaining the carriers motion emphasizes the MBBR technology's efficiency and effectiveness, making it a game-changing solution in the field of wastewater treatment.

The Internal Workings of an MBBR System

The MBBR operational principle is both innovative and efficient. When wastewater enters the treatment tank, it interacts with biofilm-coated transporters. These carriers, lifted by the aeration system's bubble stream, ensure that the wastewater and biofilm come into touch. This interaction increases the degradation of contaminants by microorganisms in the biofilm. A strategically placed sieve near the tank's exit retains the carriers in the system, allowing only treated water to depart, ready for further processing or disposal in a secure manner.

Superiority Over Traditional Treatment Approaches

The MBBR system stands out from conventional wastewater treatment methodologies for several reasons:

Space Efficiency: Its compact design is a boon for facilities where space is at a premium, allowing for effective wastewater treatment without the need for sprawling infrastructure. Sim

plicity in Operation: MBBR's automated nature reduces the need for constant human oversight, simplifying wastewater management operations.

Maintenance Ease: The self-regulating nature of biofilm growth on the carriers reduces the need for frequent maintenance interventions that are common in other systems. Remarkable Efficiency: Thanks to the constant motion of the carriers and the extensive surface area for biofilm, MBBR achieves high levels of pollutant removal in relatively short periods.

Adaptive Performance: Capable of handling varying loads and influent qualities, MBBR maintains consistent treatment efficacy, making it a reliable choice for diverse applications. Eco-friendly Solution: By promoting water reuse and minimizing the ecological impact of wastewater treatment, MBBR aligns with global sustainability goals.

Broad-Spectrum Applications: From Industry to Municipality

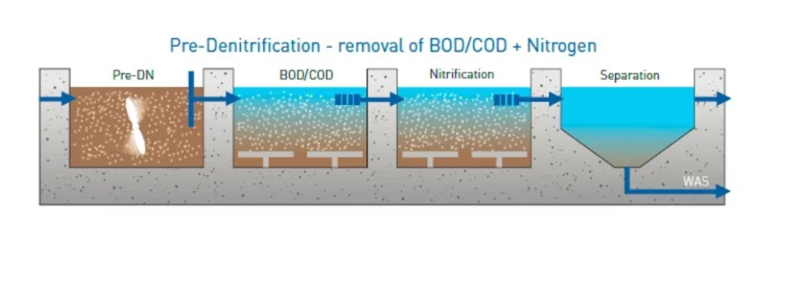

MBBR's scalability and efficiency make it an appropriate choice for a variety of wastewater treatment scenarios, including municipal and industrial applications. MBBR can benefit industries like pulp and paper, chemical manufacturing, food and beverage manufacturing, and municipal wastewater treatment plants by removing pollutants, reducing organic matter, and managing nutrients through nitrification and denitrification processes.

Benefits of MBBR over Traditional Processes:

When compared to more traditional biological wastewater treatment methodologies such as activated sludge and trickling filter systems, the Moving Bed Biofilm Reactor (MBBR) stands out for its inventive and sophisticated approach to addressing the numerous challenges inherent in wastewater management. The design and operational models of MBBR provide a significant improvement in process stability, easing the complications associated with operating and maintaining wastewater treatment facilities. This advanced technology offers a quick and efficient method to delivering high-quality water treatment results, establishing a new standard in the area. MBBR provides a consistent and robust treatment process by cleverly taking advantage of the dynamic mobility of biofilm-coated carriers within an aerated environment, eliminating the hazards of system blockages and the costly maintenance schedules that frequently afflict traditional treatment setups.

MBBR's competitive advantage over conventional methods is further demonstrated by its ability to seamlessly integrate into existing wastewater treatment regimens, providing a scalable and adaptable solution that improves overall treatment capacity without requiring large infrastructure changes. This technique effectively addresses the frequently encountered issues of operational inefficiency and high maintenance needs associated with traditional biological treatment systems. By doing so, MBBR not only guarantees a more robust and reliable treatment process, but it also introduces operational simplicity, which significantly reduces manpower and wastewater management costs. In summary, MBBR's ground-breaking method not only fulfills today's wastewater treatment needs, but also provides a forward-thinking solution capable of meeting the changing expectations of environmental stewardship.

Envisioning the Future of Wastewater Treatment

MBBR technology is poised to have a critical role in the future of the treatment of wastewater, owing to its ability to meet and surpass severe effluent quality standards. MBBR's operational benefits, in addition to its contribution to environmental preservation, establish it as a key technology in the development of sustainable and effective wastewater treatment techniques.

Conclusion: MBBR as a Beacon of Innovation in Wastewater Management

The advent of MBBR bioreactor technology represents a paradigm shift in wastewater treatment, offering a blend of performance, simplicity, and environmental compatibility. This technology not only addresses the immediate challenges of wastewater purification but also sets the stage for future advancements in water management practices. As the world gravitates towards more sustainable living standards, MBBR stands as a testament to human ingenuity and our commitment to protecting the planet's water resources for generations to come.