This article outlines the process flow for a waste to energy plant that converts organic waste into bio-compressed natural gas (bioCNG). The process involves several key stages, including waste collection, preprocessing, anaerobic digestion, biogas purification, and bioCNG compression. The following sections detail each step in the process, providing a clear understanding of how organic waste is transformed into a renewable energy source.

1. Waste Collection

The process begins with the collection of organic waste from various sources, such as households, restaurants, and agricultural operations. This waste typically includes food scraps, yard waste, and agricultural residues.

2. Preprocessing

Once collected, the organic waste undergoes preprocessing to remove contaminants and prepare it for anaerobic digestion. This stage may involve:

Sorting: Manual or mechanical separation of non-organic materials.

Shredding: Reducing the size of the organic waste to enhance digestion efficiency.

Mixing: Combining different types of organic waste to achieve optimal feedstock composition.

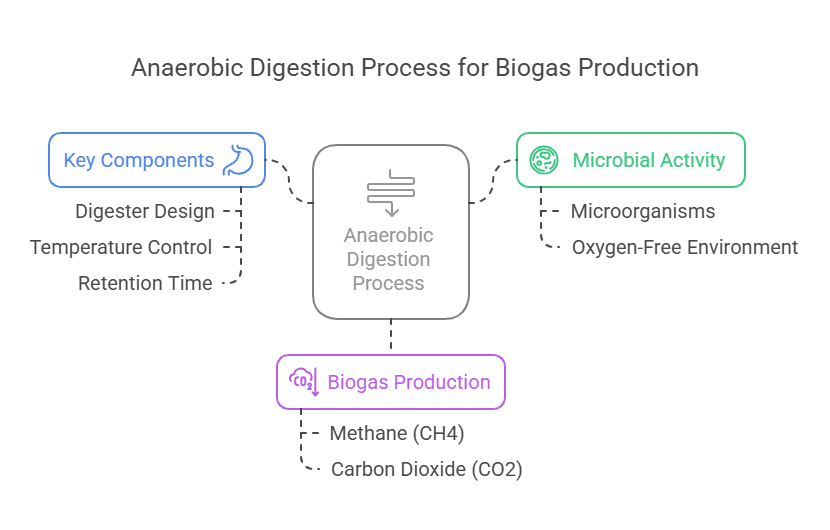

3. Anaerobic Digestion

The prepared organic waste is then fed into anaerobic digesters, where it is broken down by microorganisms in the absence of oxygen. This process produces biogas, which primarily consists of methane (CH4) and carbon dioxide (CO2). Key components of this stage include:

Digester Design: Selection of appropriate digester type (e.g., continuous stirred tank reactor, plug flow).

Temperature Control: Maintaining optimal temperature conditions for microbial activity (mesophilic or thermophilic).

Retention Time: Ensuring sufficient time for digestion to maximize biogas production.

4. Biogas Purification

The raw biogas produced from anaerobic digestion contains impurities such as hydrogen sulfide (H2S), moisture, and siloxanes. To convert biogas into bioCNG, it must undergo purification, which typically involves:

Desulfurization: Removal of hydrogen sulfide using chemical or biological methods.

Dehydration: Removal of moisture through condensation or adsorption techniques.

CO2 Removal: Separation of carbon dioxide to increase the methane concentration, often using pressure swing adsorption (PSA) or membrane separation.

5. BioCNG Compression

After purification, the high-quality biogas is compressed to produce bioCNG. This stage includes:

Compression: Using compressors to increase the pressure of the purified biogas to the desired level for storage and distribution.

Storage: Storing the bioCNG in high-pressure tanks for use as a renewable energy source.

6. Utilization

The final product, bioCNG, can be utilized in various applications, including:

Vehicle Fuel: Used as a clean alternative to fossil fuels in compressed natural gas (CNG) vehicles.

Electricity Generation: Burned in gas engines to produce electricity.

Heating: Used for heating applications in residential and industrial settings.

Conclusion

The processes at a waste to energy plant generating bioCNG illustrates the systematic conversion of organic waste into a valuable renewable energy source. By following these steps, utilities can effectively manage waste while contributing to sustainable energy solutions.

Made with Superblog

Made with Superblog