Sustainable Solutions for Soup and Broth Production: Comprehensive Waste Water Management

Soup and broth production is a global industry providing essential, ready-to-eat food products. However, the environmental impacts of this production are considerable, especially concerning water usage and wastewater generation. With the rising demand for sustainable practices, many producers are exploring eco-friendly solutions to minimize waste, reduce water consumption, and treat wastewater effectively. This blog delves into sustainable approaches in soup and broth production, focusing on reducing water waste, employing energy-efficient processes, and implementing advanced wastewater treatment techniques.

The Role of Water in Soup and Broth Production

Water is a fundamental component in soup and broth production, used throughout various stages such as ingredient washing, cooking, cooling, and packaging. These operations lead to significant water consumption and generate large amounts of wastewater, often loaded with fats, oils, grease, and organic residues like proteins and starches. If not treated properly, the wastewater can have a severe environmental impact, polluting nearby water bodies and harming ecosystems. Therefore, sustainable water management practices are essential for reducing the ecological footprint of soup and broth manufacturing.

Challenges in Managing Wastewater from Soup and Broth Production

One of the biggest challenges in soup and broth production is the treatment of wastewater containing organic matter, fats, oils, and salts. These elements, particularly fats and oils, can cause blockages in drainage systems and interfere with wastewater treatment processes. Additionally, the high organic load in the wastewater leads to elevated levels of biological oxygen demand (BOD) and chemical oxygen demand (COD), both of which require effective treatment to meet discharge regulations.

Salt, often used as a preservative in broth production, can further complicate wastewater treatment. Excessive salt content can disrupt biological treatment systems and make the reuse of water more challenging. As the industry grows, finding solutions to manage these challenges is critical to achieving sustainability in soup and broth production.

Pre-Treatment Solutions

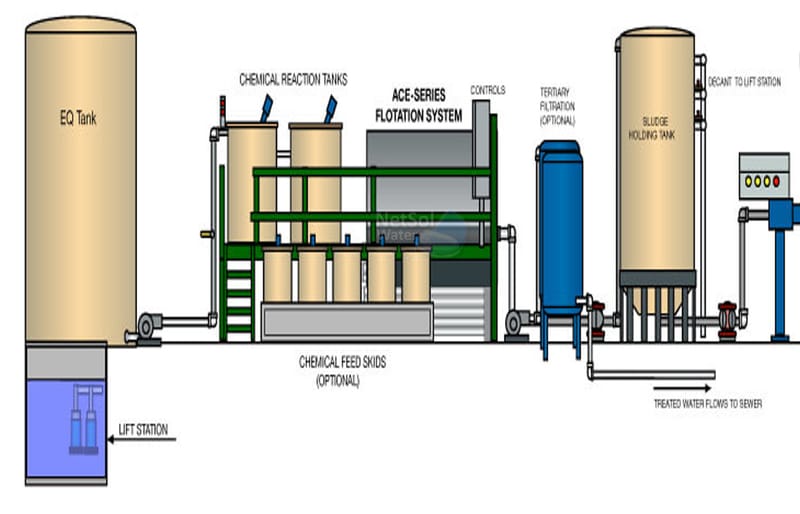

Pre-treatment is the first step in sustainable wastewater management for soup and broth production. This process involves removing large particles, fats, and oils from wastewater before it moves on to more complex treatment stages. Simple yet effective methods include screens, filters, and oil separators to capture suspended solids and grease. These pre-treatment steps reduce the organic load, easing the burden on downstream treatment systems and preventing blockages in the pipes.

Oil and grease traps are particularly useful in this context, as they separate fatty substances from the wastewater. Capturing fats and oils at this stage prevents clogging and ensures that wastewater entering the treatment system is cleaner, allowing for more efficient treatment processes.

Biological Treatment for Organic Waste

Soup and broth production generates wastewater rich in organic matter, making biological treatment systems essential. Aerobic treatment methods, such as activated sludge or trickling filters, introduce oxygen into the wastewater, promoting the growth of bacteria that degrade organic materials. This helps in significantly lowering the BOD and COD levels.

Anaerobic digestion is another effective method, breaking down organic matter in the absence of oxygen. This process generates biogas, which can be captured and used as a renewable energy source, reducing the plant’s carbon footprint. By treating wastewater with anaerobic digestion, producers can turn waste into a resource, contributing to both environmental sustainability and energy efficiency.

Membrane Filtration for Advanced Water Treatment

Membrane filtration technologies, such as ultrafiltration (UF) and reverse osmosis (RO), are widely used in the food and beverage industry for treating wastewater and recovering water. In soup and broth production, ultrafiltration can help remove fine particulates, oils, and proteins from wastewater, allowing the water to be reused for non-potable applications like cleaning and cooling.

Reverse osmosis is more advanced and can purify wastewater to a higher standard, removing salts, bacteria, and dissolved solids. This is particularly useful in broth production, where salty wastewater needs to be treated before discharge or reuse. By using reverse osmosis, soup and broth producers can recover high-quality water, reduce freshwater consumption, and meet stringent discharge regulations.

Water Recycling and Reuse

Water reuse is a key element in achieving sustainability in soup and broth production. After proper treatment, wastewater can be recycled for various purposes within the plant. For example, treated water can be used for equipment cleaning, cooling, or even as part of the production process for non-potable applications.

Implementing a closed-loop water system, where water is continuously treated and reused, can drastically reduce the plant's reliance on fresh water sources. This not only conserves water but also reduces wastewater discharge, lowering the environmental impact and operating costs.

Reducing Water Consumption Through Efficient Practices

In addition to wastewater treatment and recycling, minimizing water usage at the source is an effective way to promote sustainability. Simple yet impactful measures can be implemented, such as installing low-flow nozzles for washing and rinsing, automating water usage with shut-off valves, and optimizing cleaning-in-place (CIP) systems to use less water while maintaining hygiene standards.

Another way to reduce water consumption is by reusing water from the cooking process. In soup and broth production, water used to cook vegetables or meat can be repurposed to create broths, maximizing the use of water and reducing waste.

Energy-Efficient Production Methods

Sustainability in soup and broth production goes beyond water management—energy efficiency is equally important. By adopting energy-efficient production methods, producers can reduce their carbon footprint and lower operational costs. Heat recovery systems, for example, can capture waste heat from cooking processes and reuse it to preheat water or other ingredients, reducing the overall energy consumption of the plant.

Moreover, switching to renewable energy sources, such as solar or wind power, can help soup and broth manufacturers further reduce their environmental impact. By integrating energy-efficient technologies into their operations, producers can create a more sustainable production cycle while maintaining product quality.

Sludge Management and Resource Recovery

Sludge is a byproduct of wastewater treatment that needs to be managed effectively. In soup and broth production, sludge is often rich in organic matter and can be repurposed through composting or anaerobic digestion. Anaerobic digestion not only reduces the volume of sludge but also produces biogas, which can be used to power the plant or be sold as a renewable energy source.

Composting is another option for managing organic sludge, converting it into a nutrient-rich soil conditioner. This process reduces waste sent to landfills and provides an eco-friendly solution for managing byproducts of the wastewater treatment process.

Conclusion

The soup and broth production industry is heavily reliant on water, making sustainable water management practices essential for minimizing environmental impacts. By adopting eco-friendly solutions—such as advanced wastewater treatment systems, water recycling, and energy-efficient production methods—producers can significantly reduce their water usage, treat wastewater effectively, and contribute to a more sustainable food system.

Sustainable soup and broth production not only helps protect water resources and ecosystems but also leads to operational cost savings and improved resource efficiency. As consumer demand for eco-friendly products continues to grow, companies that implement these sustainable practices will be better positioned to meet market expectations and regulatory requirements. By embracing these innovations, the soup and broth industry can lead the way toward a more sustainable future for food production.