Sustainable Practices in Tea Processing: A Focus on Wastewater Treatment

Introduction to Sustainable Tea Processing

Tea processing is an integral part of the global food and beverage industry, with millions of tons of tea produced annually. However, the process requires large amounts of water and energy, often resulting in significant wastewater generation. With growing concerns about sustainability and environmental protection, the tea industry is now focusing on improving wastewater treatment practices to reduce its ecological footprint.

Understanding the Challenges of Wastewater in Tea Production

Water plays a critical role in various stages of tea production. From washing leaves to cooling machinery, water is essential, but it also generates substantial wastewater. The key sources of wastewater in tea processing include leaf washing, fermentation, drying, and equipment cleaning. Wastewater from these processes can contain organic materials, chemicals, and other pollutants. Therefore, addressing wastewater treatment is a critical component of sustainable tea processing.

The main challenges in wastewater management include high organic content, chemical contaminants, and water-intensive processes. Wastewater from tea processing is rich in organic materials such as plant residues, which can increase Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD) in water bodies, depleting oxygen levels and harming aquatic ecosystems. Additionally, pesticide residues, detergents, and sanitizers used in washing and cleaning processes can contaminate the wastewater, posing risks to both water sources and the surrounding environment. Efficient use of water and effective wastewater treatment are crucial for maintaining environmental balance.

Innovative Wastewater Treatment Solutions

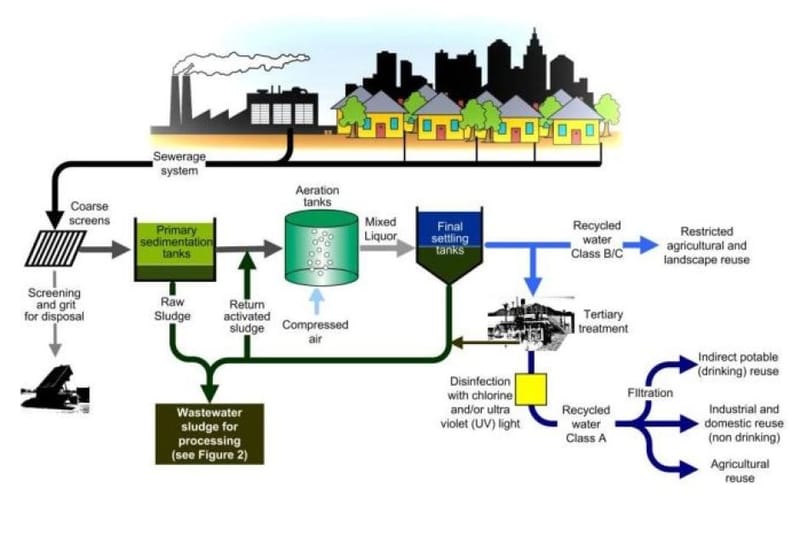

Biological treatment methods offer a sustainable solution for reducing pollutants, particularly given the high organic content of tea processing wastewater. Anaerobic digestion involves breaking down organic matter in the absence of oxygen, producing biogas, which can be used to generate energy. This method not only treats wastewater effectively but also converts waste into a renewable energy source, reducing reliance on fossil fuels. Aerobic treatment processes use oxygen and bacteria to decompose organic materials, significantly lowering the BOD and COD levels in the wastewater.

Advanced filtration technologies like Reverse Osmosis (RO) and Ultrafiltration (UF) are becoming popular in the tea industry for wastewater treatment. RO systems filter wastewater through a semi-permeable membrane, effectively removing contaminants such as chemicals, salts, and organic matter. The purified water can then be reused in non-potable applications like equipment cleaning or cooling. Ultrafiltration targets larger particles and organic matter in the wastewater, ensuring cleaner discharge and enabling water reuse in several stages of production. These systems contribute to water conservation and pollution reduction by allowing tea processors to treat and reuse water efficiently.

In some tea estates, constructed wetlands are used to treat wastewater in an environmentally friendly manner. Constructed wetlands mimic natural wetlands by filtering and purifying water through soil, plant roots, and microorganisms. As wastewater flows through the wetland, pollutants are broken down and absorbed by plants, ensuring cleaner water at the outlet. This low-energy, cost-effective system not only treats wastewater but also enhances biodiversity by creating habitats for local flora and fauna. Constructed wetlands are especially useful in tea-growing regions that prioritize nature-based solutions for wastewater management.

Towards a Zero-Liquid Discharge Future

The future of wastewater treatment in tea processing may lie in Zero-Liquid Discharge (ZLD) systems, which aim to eliminate all liquid waste from the production process. ZLD systems use a combination of filtration, evaporation, and condensation to recover almost all water used in processing. Any remaining solid waste can be disposed of or repurposed as organic fertilizer or biogas substrate. Though still expensive to implement,ZLD systemsdrastically reduce the environmental impact of tea processing by enabling manufacturers to recycle virtually all of their water and minimize pollutant discharge.

Reducing water usage is an equally important aspect of sustainable tea production. Regular water audits allow tea manufacturers to track their water usage across different stages of production, identify areas of inefficiency, and implement strategies to reduce water waste. By monitoring water use, manufacturers can adopt more targeted approaches to conservation. Installing water-efficient equipment, such as low-flow nozzles for cleaning and water-saving systems for leaf washing, helps tea processors reduce their overall water consumption. Additionally, re-engineering processes to use water more efficiently, such as dry cleaning methods or mechanical leaf washing, can greatly decrease water usage.

Educating employees about the importance of water conservation and sustainable practices is another key component in reducing water consumption. By instilling a culture of environmental responsibility, tea companies can ensure that workers adopt water-saving habits, further enhancing sustainability across the production process.

A promising eco-friendly wastewater treatment method for tea processing involves using specific plants to clean contaminated water. This technique, known as Phytoremediation, uses plants like water hyacinth to absorb or degrade pollutants in the wastewater. These plants have the natural ability to take up heavy metals, pesticides, and other contaminants from the water, either detoxifying or storing them. Phytoremediation is an excellent low-cost solution for regions where conventional treatment systems may be too expensive or difficult to implement.

Conclusion: A Commitment to Sustainability in Tea Processing

As sustainability becomes a core value for consumers and industries alike, tea manufacturers are making significant strides in adopting eco-friendly wastewater treatment practices. From biological treatment methods and advanced filtration technologies to natural systems like constructed wetlands and Phytoremediation, the tea industry is embracing innovative solutions to reduce its water footprint and environmental impact.

By reducing water consumption through efficient equipment and employee awareness programs, the industry is not only contributing to the protection of precious water resources but also ensuring the long-term viability of tea production. Sustainable tea processing is no longer just an option; it’s an imperative for safeguarding the future of the industry and the environment. Through continued innovation and a commitment to sustainability, the tea processing sector can lead the way in demonstrating how traditional industries can evolve to meet modern environmental challenges.