Innovative Water Conservation Practices and Strategies in Juice Processing

Introduction to Conservation in Juice Processing

In today's rapidly evolving juice industry, the importance of effective water conservation techniques cannot be overstated. With environmental concerns escalating and water scarcity becoming more prevalent, adopting innovative methods to reduce water usage is crucial for ensuring sustainability and maintaining cost-efficiency in juice production. This comprehensive guide explores various cutting-edge approaches aimed at minimizing water consumption while upholding the high quality of juice products.

Importance of Water Conservation in Juice Processing

Water serves as a fundamental component in every stage of juice processing, from fruit washing to equipment sanitation. As the industry grapples with escalating environmental concerns and the looming specter of water scarcity, implementing robust water-saving strategies has become imperative for securing the industry's future. By prioritizing water conservation, juice producers can not only mitigate their environmental footprint but also bolster their operational resilience in the face of fluctuating water availability and escalating costs.

Water Conservation through Membrane Filtration Technologies

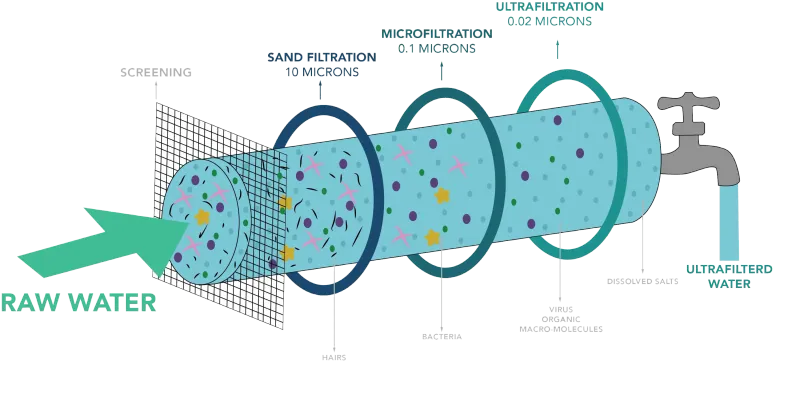

- Ultrafiltration (UF) emerges as a leading technique in the juice processing industry's efforts towards water conservation. Its significance lies in its remarkable capability to efficiently eliminate suspended solids, bacteria, and larger molecules from water streams utilized across different processing stages.

- Operating as intricate sieves, UF membranes selectively permit water molecules to pass through while capturing and retaining contaminants, resulting in water of notably higher quality.

- The water purified via UF undergoes a significant transformation, shifting from a potential waste state to a valuable resource suitable for reuse in crucial cleaning and processing tasks. This water recycling not only diminishes the industry's dependence on freshwater sources but also alleviates the environmental repercussions linked to excessive water usage.

- Additionally, UF technology promotes operational efficiency by simplifying water management practices in juice processing facilities. Integrating UF systems into their operations enables companies to enhance resource utilization, cut down costs, and bolster overall sustainability.

Nanofiltration (NF)

- Nanofiltration (NF) emerges as an innovative solution in water purification, representing a significant advancement in water conservation endeavors within the juice processing sector.

- What sets NF membranes apart is their capability to target divalent ions and larger organic molecules, thereby achieving a higher standard of water quality compared to traditional filtration methods.

- Through the selective removal of contaminants while allowing essential water molecules to pass, NF membranes play a crucial role in enhancing the purity of recycled water streams. This purified water, characterized by reduced impurities and improved clarity, becomes an indispensable resource for various processing stages.

- NF technology contributes to sustainable water management practices by optimizing water resource utilization within juice processing facilities. By incorporating NF systems, companies can minimize waste, conserve freshwater reserves, and uphold stringent quality standards, thereby enhancing their environmental credentials and operational resilience.

Reverse Osmosis (RO)

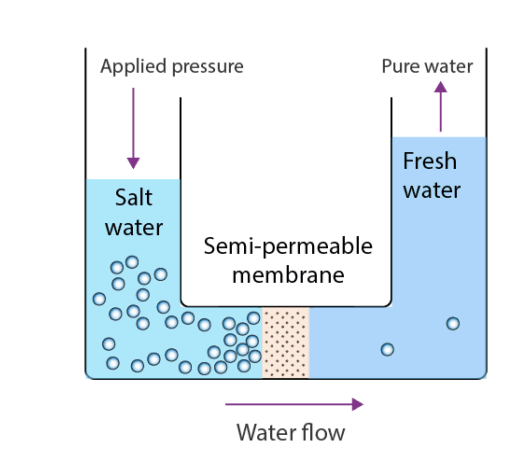

- Reverse osmosis (RO) stands as a pinnacle of innovation in the pursuit of water conservation excellence within the juice processing industry. Recognized for its exceptional purification capabilities, RO technology embodies a revolutionary approach to sustainable water management practices.

- Semi-permeable membranes form the core of RO systems, meticulously designed to selectively eliminate dissolved salts, contaminants, and other impurities from water streams. This purification process yields water of unparalleled purity, exceeding the stringent quality standards necessary for all processing needs.

- The purified water yielded by RO holds immense significance as a valuable resource within juice processing facilities. Its unmatched clarity, purity, and consistency render it indispensable for crucial processing stages, ensuring the production of top-quality juice products.

- Through the utilization of RO technology, companies can unlock a multitude of advantages, ranging from heightened product quality to minimized environmental impact. Embracing RO systems empowers juice producers to reduce water wastage, optimize resource utilization, and uphold their dedication to sustainability, positioning themselves as frontrunners in the pursuit of water conservation excellence.

Forward Osmosis: A Promising Solution

Forward osmosis emerges as a promising frontier in water conservation, presenting a sustainable alternative for juice concentration and water recovery. By leveraging the natural osmotic pressure phenomenon, forward osmosis reduces water usage and energy consumption compared to conventional concentration methods. This inventive approach not only diminishes the environmental footprint of juice processing but also yields substantial cost savings in the long run.

High-Pressure Processing for Quality and Sustainability

High-pressure processing stands as another innovative technique that prioritizes both juice quality and sustainability. By subjecting juice products to elevated pressure, this environmentally friendly method effectively eliminates pathogens while reducing water requirements for pasteurization. The preservation of nutritional integrity and sensory attributes further underscores the dual benefits of quality maintenance and environmental stewardship offered by high-pressure processing.

Water Recycling Systems: Maximizing Efficiency

At the heart of water conservation efforts in juice processing lie advanced water recycling systems. These comprehensive solutions encompass a range of techniques, including greywater recycling, condensate recovery, and closed-loop systems, all aimed at reducing waste and maximizing water reuse. By effectively capturing and treating water used across various production stages, these systems minimize environmental impact while enhancing operational efficiency and cost-effectiveness.

Zero-Liquid Discharge: Meeting Environmental Standards

Zero-liquid discharge systems represent the pinnacle of water management strategies, ensuring compliance with stringent environmental regulations by eliminating liquid waste from processing facilities. By recovering and reusing water, these systems minimize environmental impact while maximizing resource efficiency. Implementing zero-liquid discharge technologies not only demonstrates a commitment to environmental stewardship but also safeguards the industry's reputation as a responsible corporate citizen.

Smart Water Management: Real-Time Optimisation

Smart water management systems offer invaluable tools for monitoring and optimizing water usage in real-time. Leveraging advanced sensors, IoT devices, and data analytics, these systems provide insights into water flow, detect leaks, and optimize distribution, thereby identifying inefficiencies and promoting sustainable practices. By harnessing the power of technology, juice producers can streamline their water management processes, reduce waste, and minimize environmental impact while improving operational efficiency and cost-effectiveness.

Sustainable Sourcing and Processing Practices

Aside from optimizing water usage within processing facilities, embracing sustainable sourcing practices is essential for reducing the industry's overall water footprint. Initiatives such as drip irrigation and rainwater harvesting diminish water consumption in fruit cultivation, while selecting drought-resistant fruit varieties further bolsters conservation endeavors. By prioritizing sustainable sourcing and processing methods, juice producers can mitigate their environmental impact while ensuring the enduring viability of their operations.

Employee Training and Engagement: Catalysts for Change

Instillinging a culture of sustainability within juice processing facilities necessitates active engagement and involvement from employees across all levels. Offering comprehensive training on water conservation practices and highlighting the significance of sustainability cultivates a sense of ownership and accountability among staff members. By empowering employees to contribute to conservation initiatives, juice producers can enact substantive change and foster continual enhancement in water management practices.

In conclusion, Sustainability through Innovation

In conclusion, adopting cutting-edge water-saving strategies is critical to the juice industry's long-term viability and prosperity. Juice producers may save costs, increase efficiency, and satisfy consumer demand for environmentally friendly products by integrating cutting-edge technologies, streamlining operating procedures, and emphasizing sustainability throughout the supply chain. The industry may reduce its environmental effect and create the conditions for a more sustainable future by making the most of its efforts to conserve water.