The Evolution of Sludge Dewatering: Belt Filter Press vs. Decanter Centrifuge

Contents

Dewatering sludge is an essential phase in the convoluted field of wastewater treatment. Reducing the negative ecological effects of waste streams calls for constant innovation in sludge treatment and dewatering technologies. Today, we examine the differences between the two most significant inventions in the subject matter: the Belt Filter press and the Decanter Centrifuge.

The Requirement for Efficient Sludge Management Solutions

Pollution removal has become increasingly costly at a time when oil refineries are experiencing pressure to process a greater variety of feedstocks to boost earnings. As a result, the amount of sludge—a by product in the wastewater treatment plants—has increased dramatically. The need for affordable sludge treatment is greater than ever, as evidenced by the projected expansion of the market for sludge dewatering equipment, which is expected to increase from $4545 million in 2019 to $5356 million by 2025.

Belt Filter Press: The Eco-Friendly Choice

Eco-friendly: The Belt Filter Press represents out as an environmentally friendly option in the current world of environmental consciousness. It is an environmentally friendly option for sludge dewatering because of its minimal use of energy, which directly translates into a smaller carbon footprint. This feature is especially appealing to businesses that want to reduce their environmental effect.

Operational Simplicity: The Belt Filter Press's simplicity of use and the preservation is one of its best qualities. It is made to be easy enough for plant staff to do necessary maintenance without using the help of specialized technicians. This ease of use makes certain that the equipment can be maintained in top working order with the least amount of hassle, encouraging consistent performance and possibly lowering the need for expensive professional interventions.

Quick Adaptability: Because the Belt Filter Press uses an observable process, operators can respond quickly to any changes or instabilities. This ability to adapt quickly is essential for avoiding operational problems and ensuring that the dewatering process runs smoothly and efficiently. It allows for immediate adjustments, which can be critical if you want to preserve the integrity of the dewatering process.

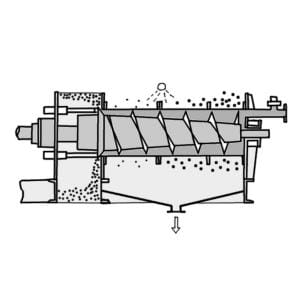

The Decanter Centrifuge is a highly efficient contender.

The Decanter Centrifuge is designed to be extremely efficient, particularly when it comes to terms of throughput capacity. This makes it ideal for larger-scale operations that require continuous sludge processing. The Decanter Centrifuge's ability to handle variable feed sludge concentrations without losing performance is a significant advantage, as it ensures consistent output regardless of changes in input material.

Less Downtime: Although the Decanter Centrifuge requires more careful maintenance, which plant personnel cannot easily make a living, its main benefit is that maintenance is less frequent. This can mean that, while there may be a higher initial skill and resource investment, longer maintenance time frames can result in less downtime overall. For operations where continuous processing is critical, reduced downtime can result in higher worker efficiency and potentially lower for a long time operational costs.

Both technologies have a place in the modern wastewater treatment landscape, and the choice between them is frequently based on specific operational needs, environmental law legal compliance and cost considerations. The Belt Filter Press is friendly to the environment as well as simple to take care of, while the Decanter Centrifuge is efficient and calls for less maintenance. Each technology offers a unique combination of advantages that can meet the varying requirements of sludge dewatering applications.

In summary, the choice between the Belt Filter Press and the Decanter Centrifuge will be determined by the wastewater treatment facility's priorities. For people who value environmental sustainability and ease of use, the Belt Filter Press is the preferred technology. Facilities that need to process large volumes of sludge with minimal interruptions may find the Decanter Centrifuge to be the better option, despite its higher energy and polymer consumption. Finally, selecting an option strikes a balance between environmental concerns and operational efficiency, tailored to the specific requirements of each wastewater treatment operation.

Choosing the Right Technology for Sludge Dewatering

The search for the best sludge dewatering technology is complicated and multifaceted. There is no universally perfect solution; the most appropriate choice is determined by a variety of factors, each of which plays an important role in the decision-making process.

Versatility vs. Specificity: The nature of the waste stream is an important consideration. Different sludges have unique properties that influence how they respond to dewatering processes. Some may have a higher organic content, while others may be more inorganic in nature, affecting their dewatering efficiency with various technologies.

Operational Scale: Facility size is another factor to consider. Smaller operations may find the Belt Filter Press more than adequate due to its scalability and ease of use. Larger facilities, on the other hand, may require the robustness and continuous operation the fact that Decanter Centrifuges provide to efficiently handle larger volumes of sludge.

Economic Factors: Budget constraints cannot be brushed aside. The Belt Filter Press generally calls for a lower initial investment and lower ongoing operational costs, which may be advantageous for facilities with limited financial resources. While the Decanter Centrifuge may require a higher initial investment and operational costs, its potential for increased throughput may justify the investment in larger plants.

Human Resources: The level of staff expertise available is also crucial. The Belt Filter Press, while straightforward, does require more frequent operator intervention and maintenance. Facilities with a well-trained operational team might find this manageable. In contrast, the Decanter Centrifuge, although more complex and requiring less frequent but more specialized maintenance, could be a better fit for facilities with access to more specialized technical staff.

The Future of Sludge Dewatering: Towards a Circular Economy

Looking ahead, the future of sludge dewatering is intertwined with the principles of the circular economy. As technology progresses, the emphasis is not only on operational efficiency but also on sustainability. Innovations are continuously being developed to reduce the cost of sludge dewatering while complying with stringent environmental regulations.

Innovation and Cost Efficiency: The future points towards technologies that can convert waste into resources, such as energy or recyclable materials, thereby reducing the overall environmental footprint. Wastewater treatment plants are not just processing facilities but are becoming resource recovery sites.

Environmental Compliance: With the rise of global environmental consciousness, dewatering technologies are also evolving to meet the stricter standards for waste management. The integration of these technologies within a circular economy framework is expected to become standard practice.

In conclusion, the evolution of sludge dewatering technologies is not only about choosing the right equipment for the present but also about adapting to the shifting paradigms of waste management. As the industry moves forward, it will continue to embrace innovative solutions that offer economic and environmental benefits, ensuring a sustainable approach to managing the essential yet challenging task of sludge dewatering.