Efficient Operations and Maintenance of wastewater treatment facilities - Save the environment and money

Optimizing Wastewater Treatment Practices in Food Manufacturing: A Comprehensive Guide

Introduction

In the ever-evolving landscape of food manufacturing, the efficient management of resources, and responsible wastewater treatment are non-negotiable. Effective wastewater treatment not only ensures compliance with stringent environmental regulations but also significantly contributes to reducing a company's ecological footprint. In this comprehensive guide, we will delve into the essential wastewater treatment practices for food manufacturers, integrating digital tools for optimization and focusing on SEO best practices.

The Imperative of Wastewater Treatment in Food Manufacturing

Wastewater generated in food manufacturing processes is notoriously complex, with varying compositions, including organic materials, fats, oils, grease, and an array of chemicals. Successful treatment of this wastewater is pivotal. Efficient wastewater treatment offers numerous benefits:

- Environmental Compliance: Meeting local and national wastewater discharge regulations is crucial to avoid legal repercussions and fines.

- Resource Conservation: Wastewater treatment not only ensures proper resource utilization but also reduces operational costs.

- Reputation Enhancement: Demonstrating a commitment to environmental responsibility can elevate a company's reputation and brand value.

Mastering Wastewater Treatment Practices

Pretreatment of Wastewater: The Importance of Screening

Waste Screening: The first step involves the removal of large solids and debris, safeguarding downstream equipment.

Primary Sedimentation Tanks: These are commonly used to separate solids from the wastewater.

Biological Treatment: Microbial Magic

Anaerobic vs Aerobic treatment: Utilize the most efficient microorganisms to break down organic matter, converting it into biomass and gases.

Chemical Treatment: The Right Chemistry

Coagulants and Flocculants: Use the correct chemicals to precipitate and settle out solids.

pH Adjustment: Ensures optimal conditions for biological treatment.

Choose the right mode of filtration: Multi-media filter vs Membrane Filtration: Precision Filtration is good but you can easily do without it.

Ultrafiltration and Reverse Osmosis: Ultrafiltration is good if you want to reuse is water for nearly potable uses but RO should be avoided as much as possible because managing rejects from RO is harder than you think and probably more harmful to the environment too.

Sludge Management: The Unsung Hero. Many people forget about the sludge. Please don't!

Dewatering: Efficiently dealing with the sludge generated during wastewater treatment. Lesser the water in your sludge, lower the sludge disposal costs. In a food plant, you can easily use the sludge for horticulture in your greenbelt.

Beneficial Reuse: Responsible management of sludge for minimizing environmental impact. There are many reuse options: 1) horticulture, 2) cooling tower make up water, 3) road cleaning, 4) construction, 5) toilet water

Water Reuse: Sustainability in Action. Systems designed for recycling treated water within the manufacturing process.

Integrating Digital Tools for Optimization

Here are some must dos that will help you operate your newly constructed wastewater treatment plant more efficiently.

Digital Log Book: Ensuring Transparency and Accessibility

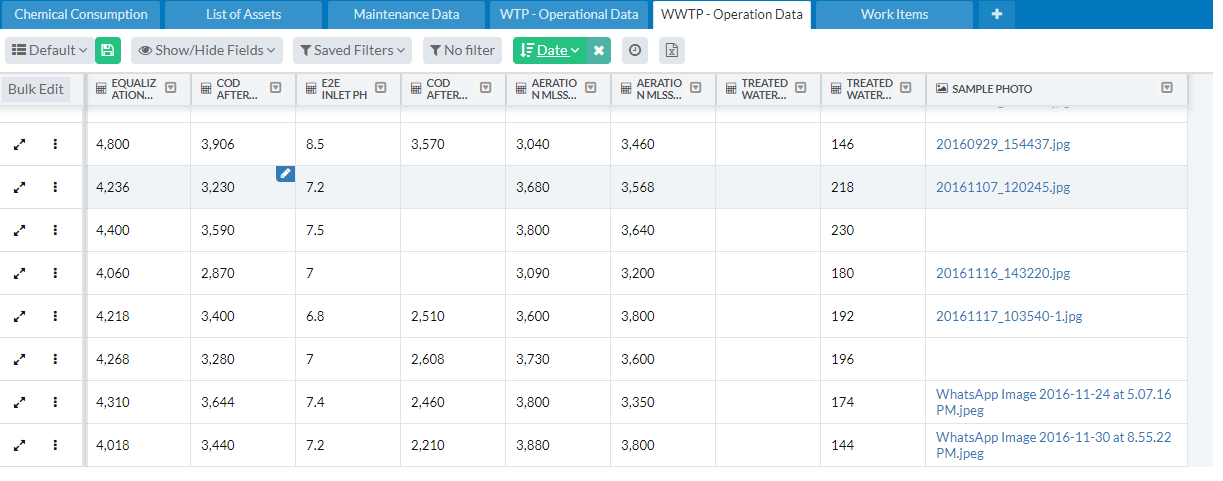

Maintain a digital log book that records all operational data, maintenance records, and observations, making them easily accessible to the team for efficient monitoring and troubleshooting.

Daily Wastewater Sample Pictures: Real-Time Monitoring

Capture daily wastewater sample images at all stages of treatment and share them with the entire team, facilitating real-time evaluation and quick corrective actions.

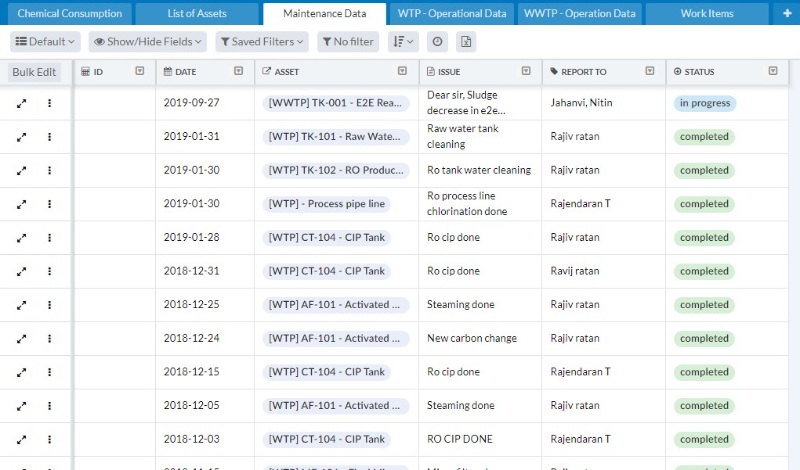

Asset Maintenance Records: Asset Management Software

Employ Asset Management software, such as Orgzit.com, to track and schedule maintenance for equipment, ensuring optimal performance and minimizing downtime.

On-Site Laboratory: Data-Driven Decision-Making

Establish an on-site laboratory for basic Total Suspended Solids (TSS) and Chemical Oxygen Demand (COD) testing, enabling regular monitoring of effluent quality and adjustments as needed.

Having an onsite laboratory for conducting essential testing, such as monitoring pH levels, Oxidation-Reduction Potential (ORP), and collecting hour meter readings for various pumps, offers numerous benefits that are integral to effective wastewater treatment and overall operations and maintenance (O&M) in food manufacturing. Let's delve into the advantages in more detail:

Real-Time Data Analysis: Onsite laboratories enable you to access data in real time, allowing for immediate assessment of water quality and equipment performance. This real-time monitoring provides insights into whether the treatment system is running optimally or if any adjustments are needed.

Timely Adjustments: With a laboratory at your facility, you can quickly respond to any deviations in pH levels or ORP, making immediate adjustments to maintain treatment efficiency. This proactive approach minimizes the risk of non-compliance with regulatory standards and ensures the consistent quality of treated water.

Predictive Maintenance: Regular analysis of hour meter readings for pumps and other equipment helps in predicting maintenance needs. You can detect signs of wear and tear, inefficiencies, or potential breakdowns early, preventing costly downtime and extensive repairs.

Process Optimization: Data collected through onsite testing allows you to fine-tune your wastewater treatment processes. By understanding the intricacies of the system in real time, you can make adjustments for optimal performance, including the precise addition of chemicals, alterations to treatment times, or other process refinements.

Cost Savings: Timely adjustments and predictive maintenance can significantly reduce operational costs. By preventing equipment failures, minimizing energy usage, and optimizing chemical dosing, you can save money in the long run.

Environmental Impact Reduction: Effective wastewater treatment is not only about regulatory compliance but also about reducing the environmental impact. Onsite testing helps ensure that treated effluent meets environmental standards, ultimately preserving natural resources and ecosystems.

Quality Assurance: Maintaining an onsite laboratory allows for rigorous quality control. You can verify that your treatment processes consistently produce effluent of the desired quality, safeguarding your reputation and ensuring the end product's safety.

Research and Development: An onsite laboratory can serve as a hub for research and development, enabling you to experiment with new treatment techniques and technologies. This fosters innovation and continuous improvement in your wastewater treatment practices.

Customization: Every wastewater treatment system is unique. Having an onsite laboratory means you can tailor your testing and monitoring protocols to the specific needs and challenges of your facility, optimizing treatment for your situation.

Regulatory Compliance: By having immediate access to accurate data, you can provide regulators with real-time evidence of compliance, making audits and reporting procedures smoother and less time-consuming.

In summary, an onsite laboratory provides food manufacturing companies with the tools needed for proactive, data-driven decision-making. The ability to analyze water quality, equipment performance, and operational data in real time allows for precise adjustments, improved efficiency, cost savings, and a reduced environmental footprint. It's an investment that not only ensures wastewater treatment compliance but also contributes to overall operational excellence and sustainability.

Conclusion

Efficient wastewater treatment practices, complemented by digital tools and data-driven approaches, are indispensable in the sustainable operation of food manufacturing companies. In addition to regulatory compliance, these practices reduce environmental impact, conserve resources, and bolster the company's reputation. Continuous innovation and the integration of advanced technologies can further enhance wastewater treatment efficiency in the food industry, fostering a greener and more sustainable future.

Remember that wastewater treatment needs can vary between food manufacturing facilities. To craft a customized solution, consult experts and adapt wastewater treatment systems to your specific operational requirements and environmental conditions. By integrating digital tools, you'll streamline your sustainability journey and reap the benefits of optimized wastewater treatment.