Understanding the Waters of Innovation: Membrane Bioreactor (MBR) Technology

Contents

- The Rise of Membrane Reactor Technology

- The Origin of MBR Technology

- The Heartbeat of MBR: Fundamental Parameters

- The Importance of Shear and Specific Aeration Demand

- MBR vs. Conventional Processes: Comparative Advantage

- Environmental and Operational Advantages of MBR

- The Future of Water Treatment: MBR at the Helm.

- Conclusion: Accepting the MBR Revolution

The Rise of Membrane Reactor Technology

A quiet revolution in the field of environmental engineering and wastewater management is taking place with an opportunity of impacting our approach to water purity and conservation. At the center of this development is Membrane Bioreactor (MBR) technology, which brings together advanced biological treatment processes with cutting-edge membrane filtration. As we learn more about the MBR and its operational features, we realize how this technology has the potential to transform wastewater treatment plants into bastions of efficiency and sustainability.

The Origin of MBR Technology

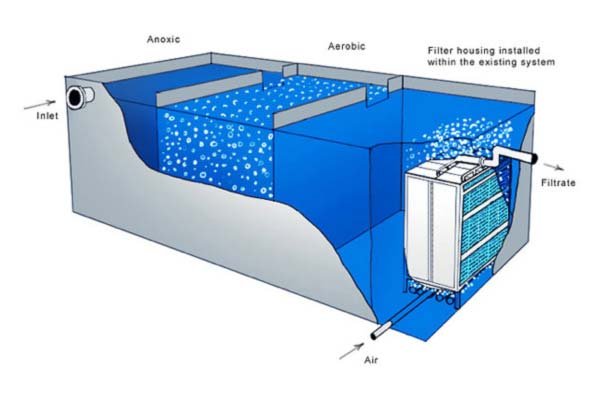

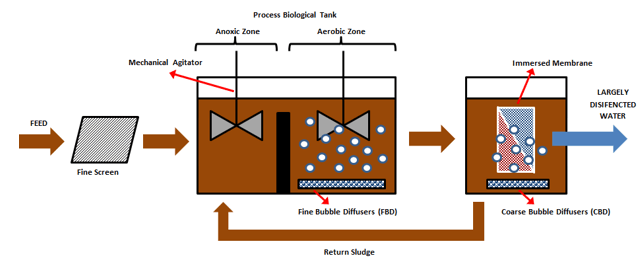

MBR technology began in the late 1980s, when a visionary team of Norwegian researchers came up with the concept. Their goal was simple but ambitious: to overcome the limits of conventional wastewater treatment systems. The brilliance of MBR technology is wrapped in its utilization of polyethylene carriers, which act as a breeding environment for biofilm. These carriers, which float freely in an aerated tank, form a dynamic environment in which microorganisms fight furiously to clean up entering wastewater.

This novel technique brings together all the benefits of biological treatment with the precision of membrane filtration. As a result, MBR systems have become increasingly prevalent in municipal and industrial wastewater treatment facilities, ushering in a new era of water treatment efficiency.

The Heartbeat of MBR: Fundamental Parameters

At the very heart of Membrane Bioreactor (MBR) technology is a complex network of operational parameters, each of which plays an important part in determining the system's functioning and efficiency. The concept of flux is important to this network; it refers to the pace at which water moves through the membrane in relation to its surface area. This metric, often stated in quantities such as litres per meter squared per hour (LMH) or gallons per foot squared per day (GFD), acts as the membrane process's heartbeat, providing a measumembrane filtrationrable indicator of its efficiency. The range of operating flux, which can range from 10 to 150 LMH, demonstrates MBR systems' amazing precision and versatility in the area of water treatment, highlighting their capacity to customize treatment processes to suit different demands with unparalleled accuracy.

As water moves through the membrane, it creates a phenomenon known as transmembrane pressure (TMP), a critical parameter that encapsulates the core of the system's pressure dynamics. This quantity, which can be defined in units like as bar, psi, or kiloPascals, is critical to understanding how MBR systems manage and control water flow under different pressure situations. The interplay between flux and TMP results in the derivation of permeability, an informative metric that reflects the membrane's ability to facilitate water flow while effectively opposing pressure. This complicated interaction between flow, TMP, and permeability exemplifies what distinguishes MBR technology as a hybrid of art and science: a beautiful balance between technological precision and a deep grasp of fluid dynamics.

This investigation of the fundamental parameters of MBR technology not only illuminates the operational complexities of these systems, but also illustrates the skill required to improve their performance. The subtle dance between flux, transmembrane pressure, and permeability shows the delicate balance that must be maintained for effective water treatment. The actual genius of MBR technology emerges from this delicate balance, demonstrating the innovation and scientific acumen that underpin its creation and implementation in water treatment. As we delve deeper into the operational backbone of MBR systems, we get a greater awareness for the complexities of these technologies, as well as a deep admiration for the advances they represent in our continued search for sustainable water management solutions.

The Importance of Shear and Specific Aeration Demand

In the field of MBR, attaining the ideal environment for membrane filtration consists of more than simply regulating flux and pressure. The flow of water or air parallel to the membrane surface produces shear, which is extremely important in preventing fouling and ensuring efficient treatment of water. For immersed membrane bioreactors, the specific aeration demand (SADp) comes into play, measuring the ratio of air used to permeate flow generated. This unitless quantity demonstrates the elegance of MBR's design, and shows that every breath of air and drop of water is considered in the pursuit of cleanliness.

MBR vs. Conventional Processes: Comparative Advantage

When examined alongside standard biological treatment procedures, MBR's superiority becomes evident. Its novel design improves process stability, operational simplicity, and efficiency, solving the frequent problems of clogging, costly maintenance, and inefficiency that afflict traditional systems. MBR technology not only matches today's wastewater treatment demands, but it also establishes new standards for future development.

MBR Configurations and Applications.

MBR technology's versatility is demonstrated by its two basic configurations: submerged and side stream. Each satisfies a specific operating need, with submerged systems favoured for medium to large sites and side stream variations suitable for smaller or more complex wastewater treatments. MBR is used in a variety of contexts, including municipal and industrial, demonstrating its versatility and efficacy in a wide range of wastewater treatment scenarios.

Environmental and Operational Advantages of MBR

Adoption of MBR technology has several environmental and operational benefits. Its modest size and high-quality effluent production make it an attractive solution for water-stressed locations and applications requiring water reuse. Furthermore, the automated features of MBR systems limit operator intervention, which speeds up the treatment process and reduces the danger of human error.

The Future of Water Treatment: MBR at the Helm.

As we face the challenges of water scarcity and environmental degradation, MBR technology provides a beacon of hope. MBR's ability to produce reusable, high-quality water, combined with its sustainability and efficiency, positions it as a key player in the future of water treatment. With ongoing development and increased global usage, MBR technology is positioned to play an important role in safeguarding our water resources for future generations.

Conclusion: Accepting the MBR Revolution

The advancement of Membrane Bioreactor technology is a major step forward in our search of sustainable water management solutions. MBR is an economical, effective, as well as an environmentally friendly wastewater treatment method that combines biological treatment with advanced membrane filtration. As we continue to develop and optimize this technology, the promise of clean, sustainable water becomes more attainable, ushering in a new era of innovation and environmental care.