The Wastewater Treatment Process for Potato: An In-Depth Guide

Introduction

Potato processing, a vibrant and beloved industry, brings us some of our favorite snacks, from crispy potato chips to savory potato wafers. However, behind the tantalizing flavors lies a crucial aspect that often goes unnoticed—the generation and management of wastewater. The production of these delectable snacks creates a significant volume of wastewater, and understanding its composition and the processes for treating it is essential for both the industry and the environment.

In this blog, we'll delve into the world of potato processing, exploring the wastewater generation, its unique composition, and the various treatment processes that are integral to ensuring responsible and sustainable production. Moreover, we'll share some key points that we have gained from the wealth of experience in designing, supplying, and operating wastewater treatment solutions for potato manufacturing plants over the last few decades years. If you're seeking guidance in this field, we're here to help. So, let's embark on a journey to uncover the fascinating world of potato processing and its commitment to a cleaner, greener future.

Typical Potato Chips Manufacturing Process

Potato chips manufacturing involves several key steps, from selecting high-quality potatoes to packaging the finished product. Here's an overview of a typical potato chips manufacturing process:

Raw Material Selection:

High-quality potatoes, typically russet or white varieties, are chosen for their ideal texture and flavor.

The potatoes are inspected and sorted to remove any damaged or spoiled ones.

Washing and Peeling:

The potatoes are thoroughly washed to remove dirt and debris.

They may be peeled to remove the outer skin, depending on the desired product. Some chips, like kettle-cooked chips, may retain the skin for added texture and flavor.

Slicing:

The peeled potatoes are sliced into thin, uniform slices using specialized slicing machines.

The thickness of the slices can vary depending on the type of chips being produced.

Blanching:

The sliced potatoes are briefly blanched in hot water or steam to soften them and remove excess sugars.

This step helps maintain the chips' color and prevents them from turning brown during frying.

Frying:

The potato slices are fried in vegetable oil or other suitable frying oils.

The temperature and duration of frying vary depending on the desired chip texture and flavor.

The fried chips become crisp and develop their characteristic golden color.

Seasoning:

After frying, the chips move on a conveyor belt through a seasoning drum.

A variety of seasonings, such as salt, barbecue, sour cream and onion, or other flavors, are added to the chips as they tumble in the drum.

The seasoning adheres to the chips, providing flavor.

Cooling:

The seasoned chips are cooled to room temperature to prevent condensation in the packaging.

Cooling can involve the use of ambient air or cooling fans.

Inspection and Quality Control:

Chips undergo inspection to identify and remove any defective or off-quality pieces.

Quality control measures include checking for color consistency, seasoning distribution, and overall product quality.

Packaging:

The final chips are conveyed to packaging equipment.

They are typically packaged in a variety of formats, such as foil-lined bags, plastic pouches, or cardboard containers.

The packaging is designed to maintain freshness and prevent moisture from reaching the chips, which could affect their crispness.

Distribution:

The packaged potato chips are prepared for distribution to wholesalers, retailers, or directly to consumers. Storage and transportation conditions are carefully controlled to maintain product quality.

Wastewater generation during potato chips manufacturing

Potato chips are one of the most beloved snacks worldwide, but behind the scenes of every tasty bag lies a process that generates a significant amount of wastewater. The production of potato chips involves various stages, and each contributes to the creation of this wastewater. In this section, we will explore how wastewater is generated during potato chips manufacturing and the importance of its proper treatment.

The Slicing and Washing Stage

The journey of a potato chip begins with the selection of high-quality potatoes. These potatoes are then sliced into thin, uniform pieces, which is one of the earliest stages in chip manufacturing. After slicing, the potato pieces are washed thoroughly to remove dirt and debris. This washing process generates the first stream of wastewater. It contains the starch and other organic matter from the potatoes, as well as any contaminants that were present on the potato skins.

The Blanching and Frying Process

To achieve the crispy texture and appealing color of potato chips, the sliced potatoes go through blanching and frying. During blanching, the potato slices are briefly immersed in hot water or steam. This step helps soften the slices and remove excess sugars. The blanching water becomes another source of wastewater, containing sugars and some potato solids.

Frying is a crucial step in chip manufacturing, where the potato slices are submerged in hot vegetable oil or other frying oils. The heat and oil help create the chips' crispy texture and golden color. However, this process can also generate wastewater in the form of used frying oil, which must be properly managed and disposed of to avoid environmental issues.

Seasoning and Cooling

After frying, the chips are seasoned with a variety of flavors, such as salt, barbecue, or sour cream and onion. This seasoning is added in a rotating drum where the chips are tumbled to ensure an even distribution. The seasoning process can contribute to wastewater generation as some seasoning mix may not adhere to the chips and falls into the wastewater stream.

Once seasoned, the chips go through a cooling process to bring them to room temperature. Cooling may involve the use of ambient air or cooling fans. Although not a significant source of wastewater, the cooling stage is part of the overall process.

The Need for Proper Wastewater Treatment

Given the significant volumes of wastewater generated during potato chips manufacturing, it is essential to address this issue responsibly. Improperly managed wastewater can lead to environmental problems, such as water pollution, increased biological oxygen demand (BOD), and potential harm to aquatic ecosystems.

To mitigate these concerns, potato chips manufacturing facilities implement wastewater treatment systems. These systems use various processes like sedimentation, filtration, and biological treatment to remove contaminants, solids, and excess organic matter from the wastewater. Once treated, the water can be safely discharged into the environment or, in some cases, reused within the facility for purposes like cleaning and cooling.

Wastewater treatment not only ensures compliance with environmental regulations but also aligns with the industry's commitment to sustainability and responsible production practices. It allows manufacturers to minimize their environmental footprint and reduce water consumption.

In conclusion, while potato chips manufacturing is a beloved industry, it is not without its environmental challenges, particularly in wastewater management. Proper treatment and responsible disposal are crucial for preserving water quality and protecting our natural ecosystems. As consumers, we can support companies that prioritize sustainability and responsible manufacturing practices, further encouraging the potato chips industry to minimize its environmental impact.

Composition of Wastewater Produced During Potato Processing

Understanding the composition of wastewater generated during potato processing is essential for effective treatment and environmental management. The wastewater produced in this industry is a complex mixture of organic and inorganic components, and its composition can vary depending on the specific processes employed by the facility. Let's delve into the typical components found in potato processing wastewater and provide some sample data to illustrate their presence:

1. Organic Matter:

Starch Content: Potatoes are rich in starch, and the processing stages like washing, slicing, and blanching release starch into the wastewater. Sample data: Starch concentration can range from 500 to 2,000 mg/L.

Sugars: The blanching process removes sugars from potato slices, and these can end up in the wastewater. Sample data: Sugar concentrations can vary from 200 to 800 mg/L.

Proteins and Cellulose: Some proteins and cellulose from the potatoes may enter the wastewater, though in lower quantities. Sample data: Protein levels typically range from 50 to 150 mg/L.

2. Oil and Fats:

- Used Frying Oil: The frying step involves submerging potato slices in hot oil, which leads to the release of used frying oil into the wastewater. Sample data: Oil and fat content can vary widely but often range from 100 to 1,000 mg/L.

3. Seasonings:

- Salt and Flavorings: The seasoning stage introduces salt and various flavorings to the chips. Some of these seasonings may not adhere to the chips, ending up in the wastewater. Sample data: Salt concentrations can range from 50 to 200 mg/L, while flavorings might vary significantly based on the specific recipe.

4. Solid Particles:

- Potato Solids: Fine potato particles and small, unsellable chip fragments may be present in the wastewater. Sample data: Solid particle concentrations can range from 50 to 500 mg/L.

5. Water:

- Process Water: The water used for washing, blanching, and cooling contributes to the overall volume of wastewater. Sample data: Process water can vary significantly, typically ranging from 5,000 to 20,000 mg/L.

6. Other Compounds:

Cleaning Agents: Some detergents and cleaning agents used for equipment cleaning may find their way into the wastewater. Sample data: Cleaning agent concentrations are typically low, ranging from 1 to 10 mg/L.

Micronutrients and Trace Elements: The potatoes may contain small amounts of micronutrients and trace elements that can be released into the wastewater. Sample data: Concentrations of these elements vary and may include zinc, iron, and manganese, among others.

Understanding the composition of potato processing wastewater is crucial for designing effective treatment systems. It enables processors to tailor their treatment processes to efficiently remove or recover specific components, reduce environmental impact, and meet regulatory requirements. By treating and managing this wastewater properly, potato processing facilities can minimize their ecological footprint and contribute to sustainable and responsible production practices.

Different Wastewater Treatment Processes for Treating Potato Wafer Wastewater

The wastewater generated during potato wafer manufacturing contains a complex mix of organic and inorganic compounds, making it essential to employ effective treatment processes to ensure compliance with environmental regulations and protect natural ecosystems. Let's explore various wastewater treatment processes commonly used in the industry to address the unique composition of potato wafer wastewater:

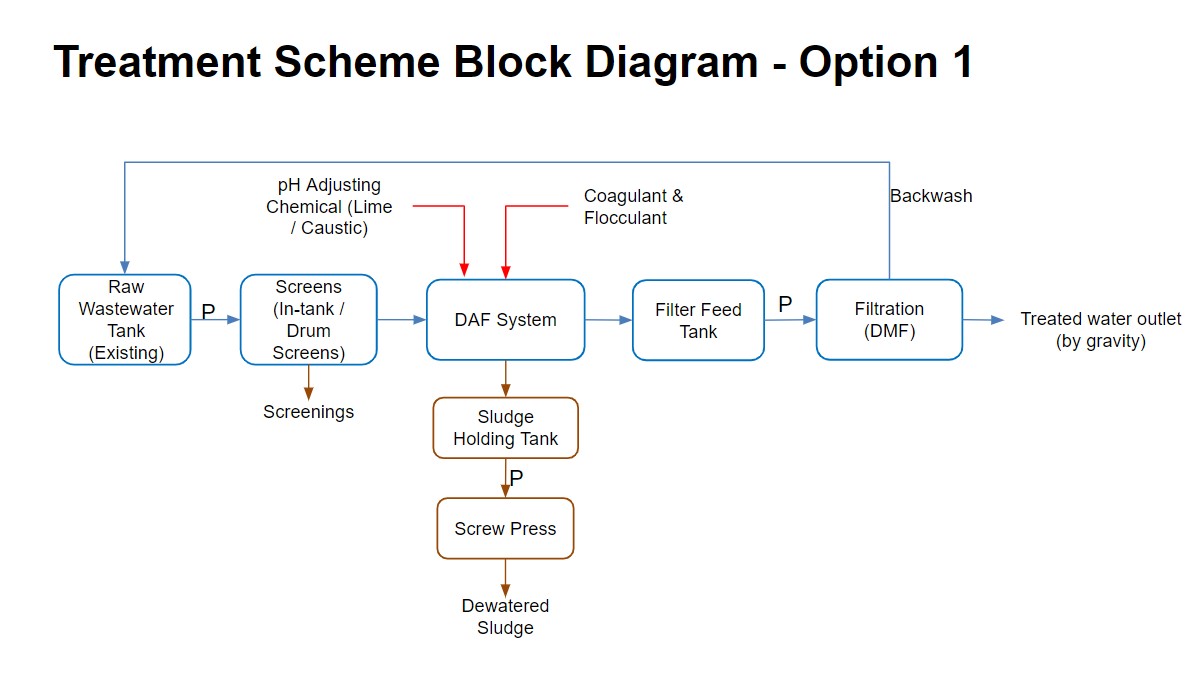

1. Primary Treatment:

Primary treatment processes involve the physical removal of solid materials and large particles from the wastewater. In potato wafer manufacturing, primary treatment may include:

Screening: The wastewater is passed through screens to remove large potato solids, peels, and other debris.

Sedimentation: This process allows heavier solid particles to settle at the bottom of a tank, forming sludge that can be later removed.

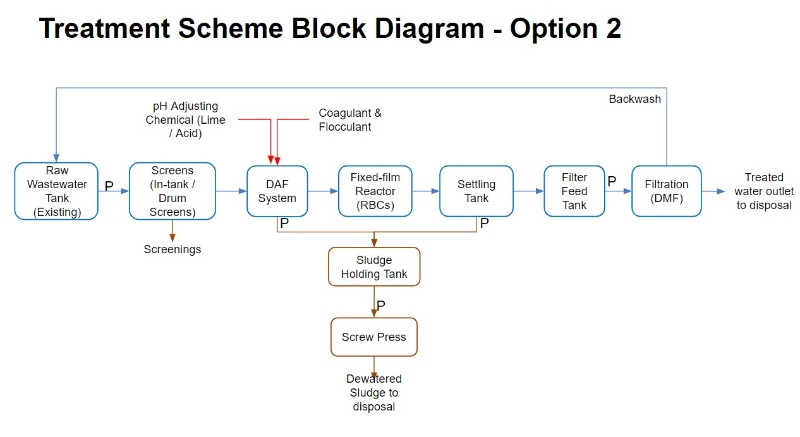

2. Secondary Treatment:

Secondary treatment processes focus on the biological degradation of organic contaminants. In potato wafer wastewater, the primary objective is to break down starches and sugars. Common secondary treatment methods include:

Activated Sludge Process: This process introduces air and microorganisms into the wastewater to accelerate the breakdown of organic matter. It is effective in reducing starch and sugar content.

Aerobic and Anaerobic Digestion: These processes use oxygen-rich and oxygen-free environments, respectively, to break down organic compounds. Anaerobic digestion can also produce biogas as a byproduct, which can be used as an energy source.

3. Tertiary Treatment:

Tertiary treatment aims to further purify the wastewater and remove any remaining contaminants. For potato wafer wastewater, tertiary treatment processes may include:

Filtration: This process involves passing the wastewater through sand or other media to remove fine suspended solids and impurities.

Chemical Coagulation and Flocculation: Chemical agents are added to promote the aggregation of fine particles, making them easier to separate from the water.

4. Advanced Treatment Technologies:

In addition to traditional treatment methods, advanced technologies are increasingly being utilized in potato wafer wastewater treatment:

Membrane Bioreactors (MBR): MBR systems combine biological treatment with membrane filtration, producing high-quality effluent with reduced solids and microorganisms.

Reverse Osmosis (RO): RO technology can be used to further purify the wastewater by removing dissolved solids and contaminants, producing near-distilled water quality.

5. Recovery and Reuse:

An important consideration in potato wafer wastewater treatment is the potential for resource recovery and water reuse. After treatment, the purified water can often be recycled within the facility for various purposes, such as cleaning or cooling, reducing the demand on freshwater resources. Additionally, some components like starch and used frying oil can be recovered and reused, further minimizing waste.

6. Compliance and Monitoring:

To ensure that the treated wastewater meets environmental standards and regulations, continuous monitoring and testing are critical. Facilities should regularly analyze the effluent to confirm compliance and make adjustments as necessary.

In summary, wastewater treatment in potato wafer manufacturing is a multi-step process that addresses the unique composition of the wastewater. By employing a combination of primary, secondary, and tertiary treatment methods, as well as advanced technologies, manufacturers can efficiently reduce the environmental impact of their operations. The responsible management of potato wafer wastewater not only safeguards the environment but also supports the sustainability and long-term success of the industry.

Conclusion

The potato processing industry, known for its delectable products like potato chips and wafers, faces a significant challenge in managing the wastewater generated during its production processes. Understanding the composition and unique characteristics of this wastewater is a crucial first step in the journey towards sustainable and responsible production.

At Spans, we have extensive experience in designing, supplying, and operating wastewater treatment solutions for potato manufacturing plants. We understand the intricacies of this industry and are committed to helping facilities meet environmental regulations, reduce their ecological impact, and promote sustainable practices. If you're looking for expert guidance and solutions to optimize your wastewater management, we invite you to connect with us. Together, we can savor the flavors of our favorite potato snacks while ensuring a cleaner, greener future.