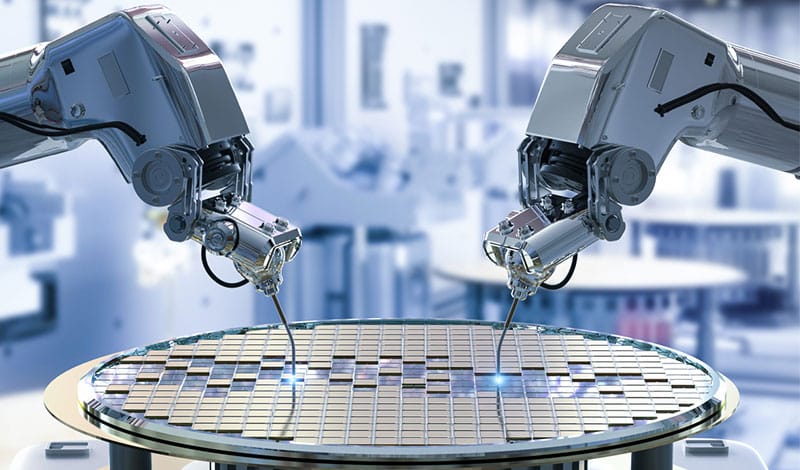

Semiconductor Industry: Advanced Oxidation for Comprehensive Wastewater Treatment

Welcome to our in-depth exploration of the semiconductor industry's wastewater treatmentlandscape. Join us as we delve into the intricacies of semiconductor manufacturing processes and the multifaceted challenges they present in terms of wastewater composition. In this blog, we will examine the revolutionary role of advanced oxidation processes (AOPs) in addressing these challenges, offering comprehensive and sustainable solutions for semiconductor fabs worldwide.

Understanding the Complexity of Semiconductor Wastewater

Semiconductor manufacturing processes are characterized by their complexity and precision, involving a myriad of steps such as chemical mechanical polishing (CMP), etching, rinsing, and more. These processes result in the generation of diverse wastewater streams, each containing a complex mixture of contaminants. Key constituents of semiconductor wastewater include:

Chelates: Complexing agents such as cyanide or phosphonobutane-tricarboxylic acid (PBTC) are commonly used in semiconductor processes and pose significant challenges for conventional treatment methods.

Organo-nitrogen Compounds: Compounds like pyrazole, triazoles, and tetramethylammonium hydroxide (TMAH) are prevalent in semiconductor wastewater and can be difficult to degrade.

Toxic Substances: Various toxic compounds, both organic and inorganic, may be present due to the use of chemicals in semiconductor manufacturing.

Compounds with Poor Biodegradability: Some organic compounds found in semiconductor wastewater exhibit poor biodegradability, posing challenges for biological treatment methods.

Excess H2O2 or Ozone: Residual hydrogen peroxide (H2O2) or ozone from rinsing processes can contribute to the complexity of semiconductor wastewater.

Spent Production Solutions: Solutions such as sulfuric acid (H2SO4) contaminated with H2O2 from etching processes require specialized treatment for safe disposal or recycling.

The Role of Advanced Oxidation Processes (AOPs)

In the semiconductor industry,wastewater treatment is a critical aspect that demands innovative solutions to address the complex composition of wastewater streams. Advanced Oxidation Processes (AOPs) have emerged as a transformative approach, leveraging innovative technologies to effectively target and degrade a wide range of contaminants.

Advantages of AOPs in Semiconductor Wastewater Treatment

Selective Degradation:

AOPs offer the capability to selectively target specific contaminants present in semiconductor wastewater. Whether it's chelates, organo-nitrogen compounds, or toxic substances, AOPs ensure comprehensive treatment and pollutant removal. This selective degradation ensures that semiconductor fabs can effectively manage and treat their wastewater streams, meeting regulatory standards and environmental requirements.

Enhanced Biodegradability:

One of the significant advantages of AOPs is their ability to enhance the biodegradability of organic compounds with poor biodegradability. By breaking down these compounds into more biodegradable forms, AOPs facilitate further treatment in downstream processes. This enhancement in biodegradability not only improves treatment efficiency but also contributes to overall environmental sustainability.

Economic Viability and Environmental Sustainability:

AOPs offer economically viable and environmentally sustainable solutions for semiconductor fabs. By minimizing chemical usage, energy consumption, and waste generation, AOPs optimize resource utilization and reduce operational costs. Moreover, the environmentally sustainable nature of AOPs aligns with the industry's commitment to corporate social responsibility, enhancing the overall reputation and competitiveness of semiconductor fabs.

Minimal Secondary Waste:

Unlike conventional treatment methods, which may produce secondary waste streams, AOPs generate minimal secondary waste. This minimization of secondary waste streamlines the treatment process, reducing environmental impact and operational complexities. Semiconductor fabs can benefit from the efficiency and effectiveness of AOPs in wastewater treatment, ensuring a more sustainable approach to semiconductor manufacturing processes.

Pioneering Sustainable Solutions in Semiconductor Wastewater Treatment

In the ever-evolving landscape of semiconductor manufacturing, wastewater treatment stands as a crucial pillar of sustainability and environmental responsibility. Enviolet emerges as a leader in this arena, offering customized Advanced Oxidation Process (AOP) solutions tailored to the unique needs of semiconductor fabs. With a focus on advanced UV-based AOP systems, Enviolet has established itself as a frontrunner in delivering efficient and effective treatment solutions that address the complex challenges of semiconductor wastewater.

Customised AOP Solutions for Semiconductor Fabs

Enviolet's expertise lies in providing tailored AOP solutions that meet the specific requirements of semiconductor fabs. By utilizing advanced UV-based technologies, Enviolet's systems are capable of treating optically dense media and addressing the intricate compositions of semiconductor wastewater. This customization ensures that semiconductor fabs receive treatment solutions optimized for their unique operational parameters and environmental goals.

Applications of AOP in Semiconductor Wastewater Treatment

Enviolet's AOP solutions find diverse applications in semiconductor wastewater treatment, offering targeted and efficient treatment for a variety of contaminants. Two key applications stand out:

Safe Removal of Chelates: Chelates, such as cyanide or phosphonobutane-tricarboxylic acid (PBTC), are complexing agents commonly used in semiconductor processes. Enviolet's UV-Oxidation, a key component of AOPs, effectively degrades these chelates, ensuring their safe removal from semiconductor wastewater. This targeted degradation ensures compliance with environmental regulations and promotes the overall safety and sustainability of semiconductor manufacturing processes.

Recycling Spent Production Solutions: Semiconductor manufacturing involves the use of various production solutions, such as sulfuric acid contaminated with compounds like hydrogen peroxide (H2O2). Enviolet's AOPs enable the recycling and purification of these spent production solutions, facilitating resource conservation and cost-efficiency. By removing contaminants like H2O2, Enviolet's solutions allow semiconductor fabs to reuse production solutions, minimizing waste generation and promoting sustainable manufacturing practices.

Looking Ahead: Towards a Sustainable Future

As the semiconductor industry continues to evolve and innovate, the adoption of sustainable wastewater treatment practices becomes increasingly imperative. Advanced oxidation processes, such as those offered by Enviolet, represent a critical step forward in achieving wastewater treatment that aligns with the industry's commitment to innovation, responsibility, and environmental stewardship.

By leveraging advanced UV-based AOP systems, semiconductor fabs can not only meet regulatory requirements but also optimize resource utilization and reduce environmental impact. As environmental consciousness becomes a central focus of semiconductor manufacturing, Enviolet's sustainable solutions pave the way for a greener and more sustainable future for the industry.

In conclusion, Enviolet stands as a pioneer in delivering sustainable wastewater treatment solutions for the semiconductor industry. With customized AOP systems tailored to semiconductor fabs' unique needs and applications spanning from chelate removal to production solution recycling, Enviolet is driving innovation and promoting environmental stewardship in semiconductor manufacturing. As the industry looks towards a sustainable future, Enviolet remains at the forefront, leading the way with its advanced UV-based AOP solutions.